Tip: Start typing in the input box for immediate search results.

-

Feature

-

Interface

-

File Operation

-

Design Central

-

Basic Setting

-

Viewing Tools

-

Object Operation

-

Drawing

-

Parametric

-

Graph Editing

-

Graph Transform

- Move

- rotate

- Transform Again

- Mirror

- Arc and Line Fit

- Envelop Distortion

- Perspective Distortion

- Push and Pull Distortion

- Twist Distortion

- Shadow Distortion

- Curve Zmap

- Auto Nesting

- Interactive Nesting

- Clone Along a Curve

- Rectangular Clone&Polar Clone

- Clone along a Line

- Clone along an Arc

- Clone along a Spiral

- Scale 2 Points

- Orient 2 lines

- 3D Move

- 3D Rotate

- 3D Scale

- 3D To XY Plane

-

Image Processing

-

Text Editing

-

Node Editing

-

Graph Toolpath

- Tool Path

- Profile Machining

- Area Clearance

- Flute Machining

- 3D Corner Engraving

- Midine Machining

- Drilling

- Insert And Inlay

- Intelligent Machining

- Prism Machining

- Embossing Machining

- Toolpath output

- Tool Management

- Toolpath Walk Simulation

- Toolpath Shaded Simulation

- Post Set

- Toolpath Regenerate

- Toolpath Stat

- Chamfer Machining

- Adaptive Area Clearance

-

Image Toolpath

-

Wireframe Toolpath

-

Toolpath Edit

-

Waveboard

-

Mesh

-

Relief Sculpt

-

Surface

- Surface

- Import Surface File

- Standard Surface

- Freeform Surface

- Chamfer Surface

- Fillet Surface

- Extend Surface

- Show Effect

- To 3D Curve

- Curve Project to Surface

- Pullback

- Extract Edge

- Split at Isocurve

- Trim at Curve

- Trim at Surface

- Untrim

- To Mesh

- Edit Node of Surface

- Insert Control Point

- Vari Fillet Surfaces

- 3D-Spline

- Surface Flatten

- Mesh Wrap

-

Canvas 3D

-

Surface Toolpath

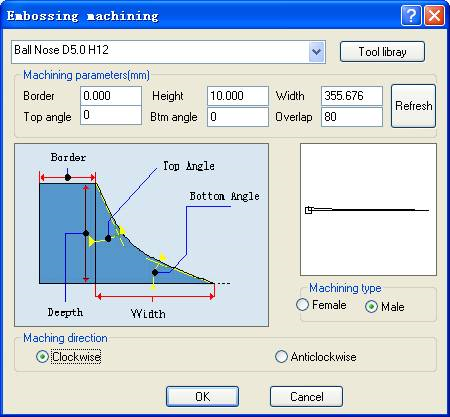

Embossing Machining

Embossing machining is mainly used in making rounded characters or shapes.

It is widely used in such fields as embossment sign boards, badge, furniture, metallic moulds, printing, etc.

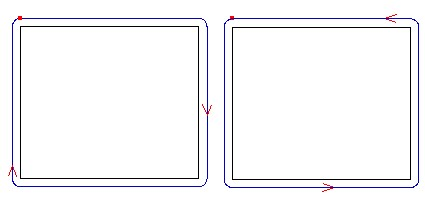

Male Female

Command:

Menu【Toolpath > Embossing machining】 Toolpath Bar

Steps:

1. Select the object.

2. ClickMenu【Toolpath > Embossing machining】.

3. Set the parameters, Click OK button.

Parameters:

1)Border: the distance between the border of the contour and the toolpath

2)Height: the total machining depth

3)Width: the width of the toolpath

4)Top angle: the angle formed by the vertical direction and the tool when it is entering the material

5)Bot angle: the angle formed by the horizontal direction and the tool when it is entering the material

6)Machining type: Male and female.

7)Machine direction: is the direction of the toolpath, including clockwise and anti-clockwise. When choosing cutting direction, the material should be taken into consideration so that the surface of the material after being machined is smooth. Clockwise machining is fit for cutting materials of high density, such as Acryl (organic glass), brass, etc; anti-clockwise machining is fit for cutting materials of low density such as PVC board, two-color board, etc.