Tip: Start typing in the input box for immediate search results.

-

Feature

-

Interface

-

File Operation

-

Design Central

-

Basic Setting

-

Viewing Tools

-

Object Operation

-

Drawing

-

Parametric

-

Graph Editing

-

Graph Transform

- Move

- rotate

- Transform Again

- Mirror

- Arc and Line Fit

- Envelop Distortion

- Perspective Distortion

- Push and Pull Distortion

- Twist Distortion

- Shadow Distortion

- Curve Zmap

- Auto Nesting

- Interactive Nesting

- Clone Along a Curve

- Rectangular Clone&Polar Clone

- Clone along a Line

- Clone along an Arc

- Clone along a Spiral

- Scale 2 Points

- Orient 2 lines

- 3D Move

- 3D Rotate

- 3D Scale

- 3D To XY Plane

-

Image Processing

-

Text Editing

-

Node Editing

-

Graph Toolpath

- Tool Path

- Profile Machining

- Area Clearance

- Flute Machining

- 3D Corner Engraving

- Midine Machining

- Drilling

- Insert And Inlay

- Intelligent Machining

- Prism Machining

- Embossing Machining

- Toolpath output

- Tool Management

- Toolpath Walk Simulation

- Toolpath Shaded Simulation

- Post Set

- Toolpath Regenerate

- Toolpath Stat

- Chamfer Machining

- Adaptive Area Clearance

-

Image Toolpath

-

Wireframe Toolpath

-

Toolpath Edit

-

Waveboard

-

Mesh

-

Relief Sculpt

-

Surface

- Surface

- Import Surface File

- Standard Surface

- Freeform Surface

- Chamfer Surface

- Fillet Surface

- Extend Surface

- Show Effect

- To 3D Curve

- Curve Project to Surface

- Pullback

- Extract Edge

- Split at Isocurve

- Trim at Curve

- Trim at Surface

- Untrim

- To Mesh

- Edit Node of Surface

- Insert Control Point

- Vari Fillet Surfaces

- 3D-Spline

- Surface Flatten

- Mesh Wrap

-

Canvas 3D

-

Surface Toolpath

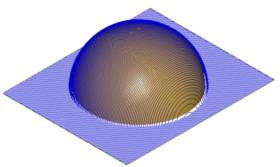

Finish Parallel

Finish Parallel is usually used for surface milling with ball nose. Finish Parallel is to machine the entire surface via parallel paths (parallel lines). The parallel linear milling can be machined at any angles.

Command:

Menu【Toolpath > Surface Finish > Finish parallel】

Steps:

1. Select surface.

2. Click Menu【Toolpath > Surface Finish > Finish parallel】.

3. Set the parameters, click OK button.

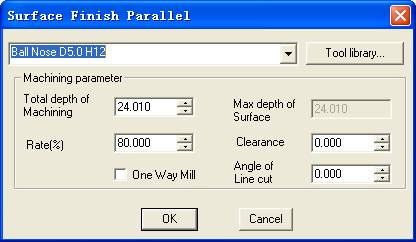

Parameters:

Total depth of Machining: the actual total depth of machining required ;

Max depth of Surface: the max depth of surface is to machine.

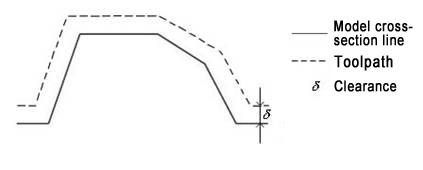

Clearance: you can set surface remain which is the shortest distance between the original surface and surface after carving.

Rate: is the ratio of the width of the tool bottom blade to the width of the last tool path.

Angle of Line cut: is the angle formed by horizontal direction and the tool when it moving on material.

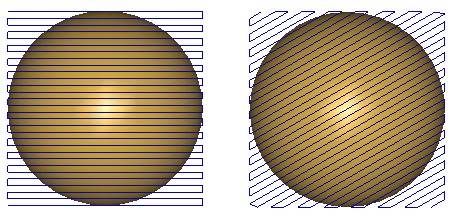

Angle 0 Angle 30

On way mill: Machining in one direction.